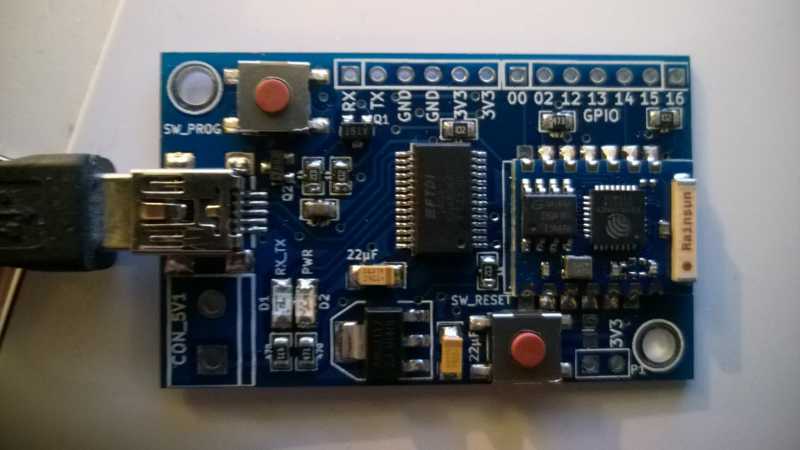

my esp8266 usb development board

today i finally received my latest shipment from china, and in it were the last parts that I needed to finish my esp-03 development pcb project. Here is the result - my "espduino" (proud):

hm, lets see if this (picture) works..edit- yep looks good. so..

The upper left push button (when pushed) pulls both ch_pd and gpio0 to ground and charges a capacitor. When the button is released, ch_pd is connected to 3v3 again and the module boots up; while the capacitor discharges slow enough to hold gpio0 to gnd during the startup of the esp8266, so that it enters bootloader/fw update mode.

The result is, i only need to press the pushbutton while the arduino IDE compilesmy sketch, and the board is ready for the upload once it starts.

The other push button is for hard-resetting the module.

Assembling everything with solderpaste, toothpick and fine tweezers took some time, reflow oven worked quite well (first time!) and the best is: the board actually works quite good.

Now on to assembling the other pcbs as well...

regards

Please Log in or Create an account to join the conversation.

Please Log in or Create an account to join the conversation.

- HarryDutch

- Offline

- Senior Member

-

- Posts: 65

- Karma: 1

- Thank you received: 11

Please Log in or Create an account to join the conversation.

One word about the thermocouple, i boughtone of those chinese kits with sensor and breakout board which was pretty useless until I stripped off the metal hull of the sensor tip. The thermocouple needs to be very responsive to get an accurate temperature reading, and the metal sensor head contained just too much air that acted as insulation.

regards

Please Log in or Create an account to join the conversation.

Please Log in or Create an account to join the conversation.

Dennis wrote: thanks. My reflow oven is a standard 1500 watt mini toaster oven with four metal heating elements. I wanted to make it ssr-controlled, but discovered that I just need to put the oven to full power for four minutes to get good results - and so the smd reflow oven controller sketch became a smd reclow oven monitor sketch, and just displays the reflow profile and temperature curve on a color lcd...

One word about the thermocouple, i boughtone of those chinese kits with sensor and breakout board which was pretty useless until I stripped off the metal hull of the sensor tip. The thermocouple needs to be very responsive to get an accurate temperature reading, and the metal sensor head contained just too much air that acted as insulation.

regards

Can you tell us which model of oven do you use? Some posts on internet recommend smaller oven because it heats faster. And also additional insulation. I just asking, because maybe I will build one, but there are so many different recommendations on internet.

Please Log in or Create an account to join the conversation.

Forum latest

- No posts to display.